Marine & Shipbuilding

FEA & CFD based Design and Optimization for Marine and Shipbuilding Industry

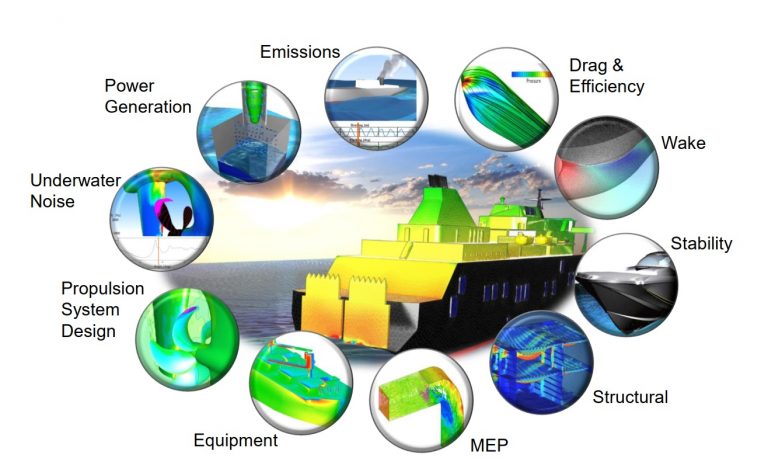

Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) are widely used in the marine and shipbuilding industry to optimize the design of ships and boats.

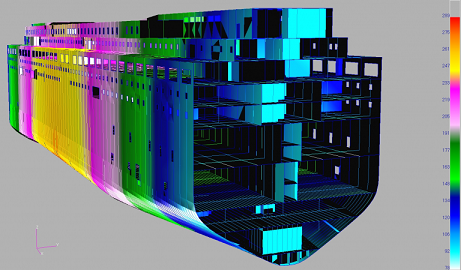

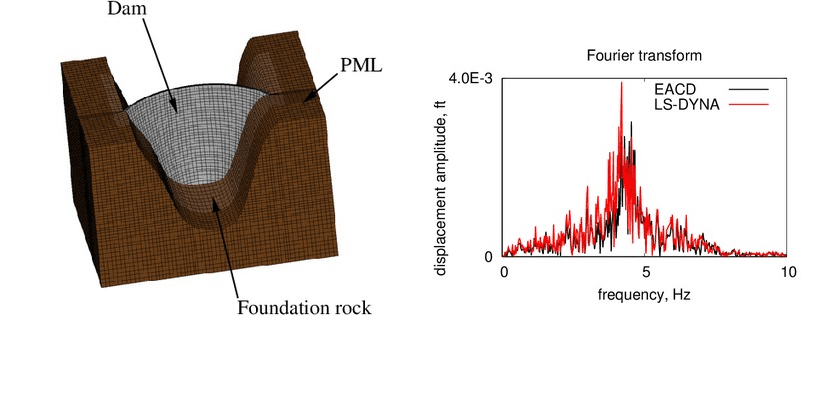

One application of FEA in shipbuilding is to analyze the structural integrity of the vessel under various loading conditions. This can include analyzing the stresses and strains on the hull, the performance of the propulsion system, and the behavior of the vessel in waves and other environmental conditions.

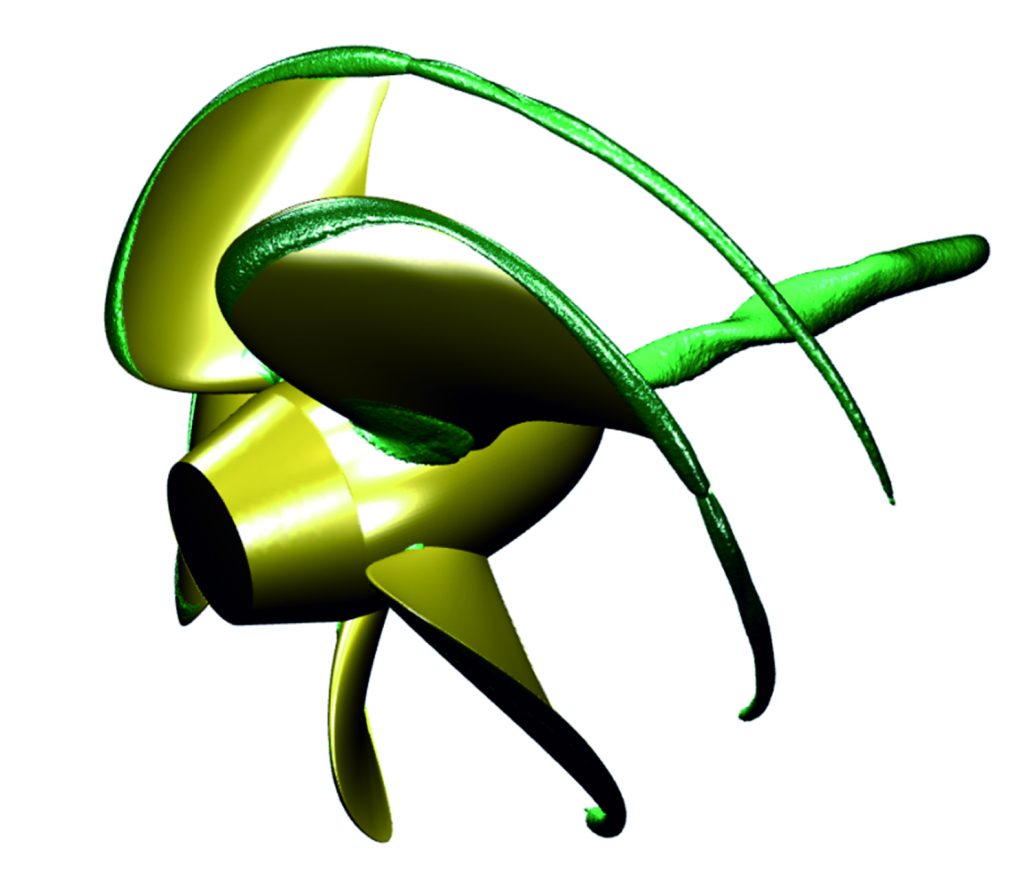

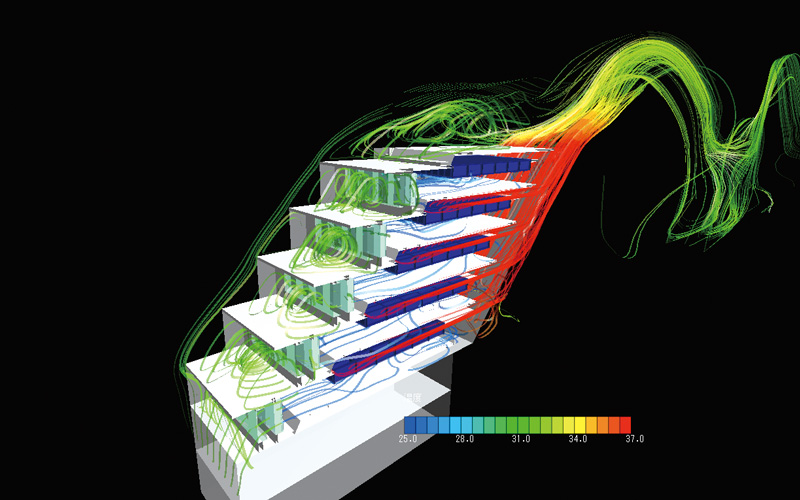

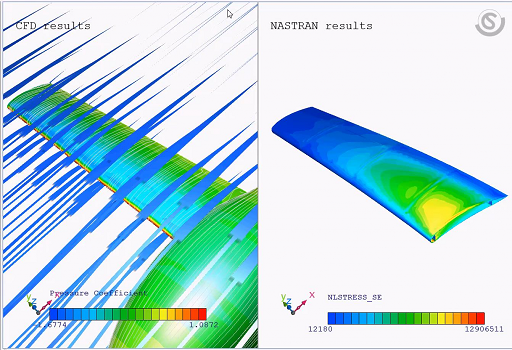

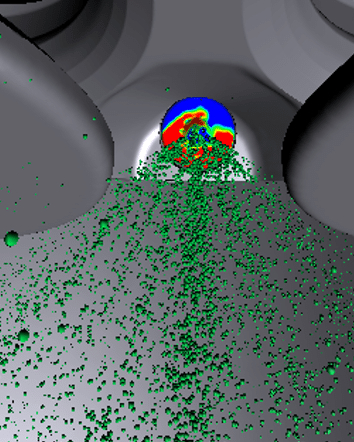

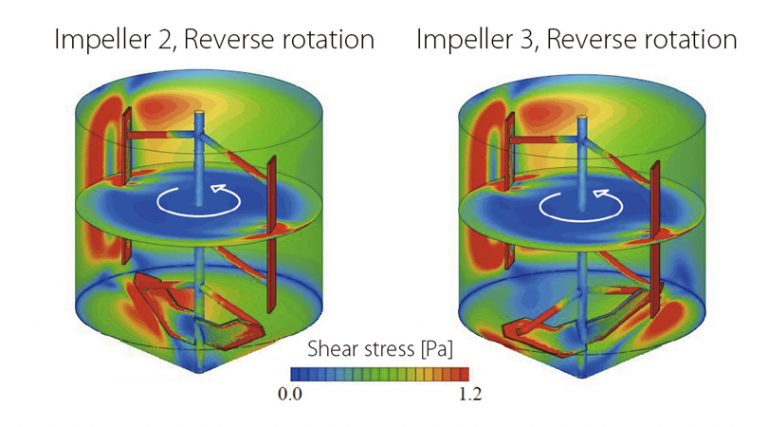

CFD simulations, on the other hand, can be used to analyze the fluid dynamics around the hull and other components of the vessel, such as the propellers and rudders. By analyzing the flow of water around these components, engineers can optimize their design to reduce drag, increase efficiency, and improve maneuverability.

Multiphysics simulations, which combine FEA and CFD, can provide even more detailed and accurate analysis of complex systems. For example, a multiphysics simulation could be used to analyze the interaction between the hull and the water, taking into account the effects of both fluid dynamics and structural stresses.

Simulation Dynamics services and expertise in FEA and CFD-based simulation can help shipbuilders and boat designers to optimize their designs, reduce costs, and improve the safety and performance of their vessels. By leveraging the power of simulation technology, the marine and shipbuilding industry can develop more efficient and environmentally friendly vessels that can withstand the challenges of the open sea.